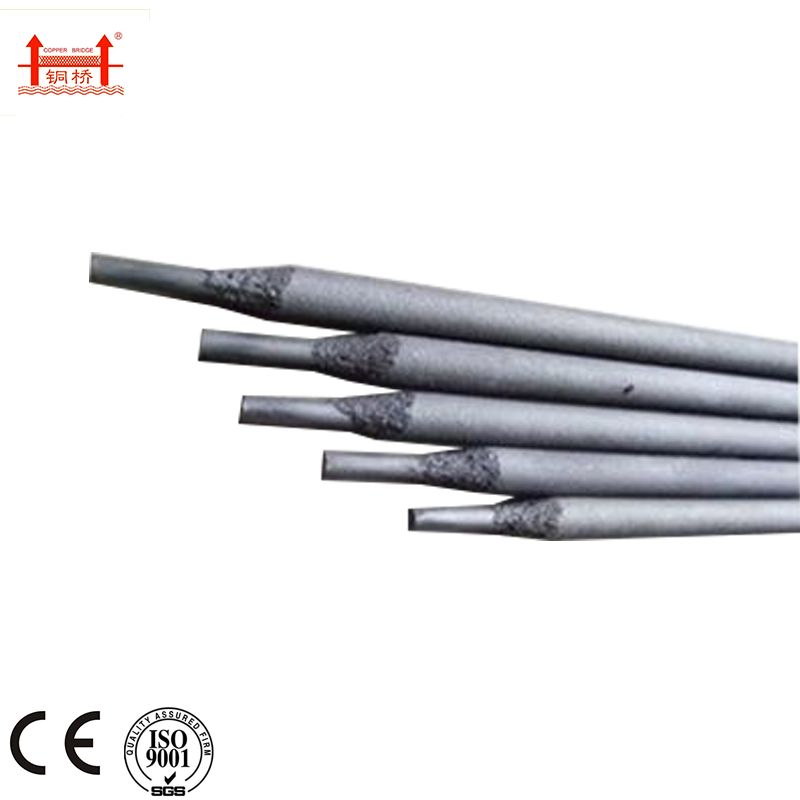

Li-electrode tsa tšepe tse se nang tšepe CB-A102

Tsebiso ea tšebeliso ea elektrode e se nang tšepe

1. chromium tšepe e sa hloekang e na le khanyetso e itseng ea kutu (oxidizing acid, organic acid, cavitation) , ho hanyetsa mocheso le ho apara ho hanyetsa.Hangata e sebelisoa ho limela tsa motlakase, lik'hemik'hale, peterole le lisebelisoa tse ling tsa thepa.Chromium stainless steel weldability e fokolang, e lokela ho ela hloko ts'ebetso ea ho tjheseletsa, maemo a phekolo ea mocheso le khetho ea electrode e nepahetseng.

2. CR-13 tšepe e sa hloekang e na le boima bo phahameng ka mor'a ho cheselletsa 'me ho bonolo ho hlahisa crack.Haeba mofuta o tšoanang oa electrode ea tšepe e sa hloekang ea chromium (G202, G207) e sebelisetsoa ho cheselletsa, e tlameha ho futhumatsoa ka holimo ho 300 ° C ebe e pholile hoo e ka bang 700 ° C ka mor'a ho cheselletsa.Haeba tjheseletsa e ke ke ea etsoa ka mor'a mocheso oa mocheso, joale khetho ea chromium-nickel steel stainless steel electrode (A107, A207) .

3. Chromium 17 tšepe e sa hloekang, e le ho ntlafatsa ho hanyetsa ha kutu le ho chesehela le ho eketsa palo e loketseng ea lintho tse tsitsitseng tse kang Ti, Nb, Mo, joalo-joalo, weldability e molemo ho feta chromium 13 tšepe e sa hloekang.Ha ho sebelisoa mofuta o tšoanang oa electrode ea tšepe e sa hloekang ea chromium (G302, G307), e lokela ho futhumatsoa ka holimo ho 200 ° C ebe e halefa ho pota 800 ° C ka mor'a ho cheselletsa.Haeba welding e ke ke ea phekoloa ka mocheso, joale khetho ea chromium-nickel stainless steel electrode (A107, A207) .Electrode ea tšepe e sa hloekang ea CR-NI e na le khanyetso e ntle ea kutu le khanyetso ea oxidation, e sebelisoang haholo indastering ea lik'hemik'hale, manyolo, peterole, tlhahiso ea mechini ea bongaka.

4. 0 le ka tlase e ka sebelisoa bakeng sa ho tjheseletsa maemo ohle.

5. 0 le ka holimo bakeng sa tjheseletsa e bataletseng le fillet.

6. Ho roala ka tšepe ea chromium-nickel ho na le mofuta oa titanium-calcium le mofuta o tlaase oa hydrogen.Calcium titanate mofuta o ka sebelisoa AC le DC, empa ho kenella ka hare ho tjheseletsa ea AC e sa tebang, ha ho le bonolo ho khubelu, e le ho sebelisa motlakase oa DC.Diameter

7. Electrode e lokela ho bolokoa e omme, mofuta oa titanium-calcium o lokela ho omisoa ka 150 ° C bakeng sa hora e le 'ngoe,' me mofuta o tlaase oa hydrogen o lokela ho omisoa ka 200 ° C ho ea ho 250 ° C bakeng sa hora e le 'ngoe (ha ho na ho omisa khafetsa, ho seng joalo. ho roala ho bonolo ho phunyeha le ho phunya) , thibela oli e khomarelang ea electrode le litšila tse ling, e le hore u se ke ua eketsa carbon content ea weld le ho ama boleng ba welding.

8. E le ho thibela kutu pakeng tsa mahlo a bakoang ke ho futhumatsa, hona joale welding ha ea lokela ho ba khōlō haholo, ka tlase ho carbon steel electrode hoo e ka bang 20%, ARC ha ea lokela ho ba nako e telele haholo, ho pholile ka potlako pakeng tsa lihlopha, ho etsa hore bead e tšesaane e be e loketseng. .

| Mohlala | GB | AWS | Diameter (mm) | Mofuta oa ho roala | Hona joale | Lisebelisoa |

| CB-A102 | E308-16 | E308-16 | 2.5-5.0 | Mofuta oa lime-titania | DC | E sebelisetsoa ho chesella 0cR19Ni9 le 0Cr19Ni11Ti meaho ea tšepe e sa hloekang ka tlase ho 300︒C |

Motsoako oa Lik'hemik'hale oa Metal e Deposited

| Motsoako oa lik'hemik'hale oa tšepe e behiloeng (%) | ||||||||

| C | Mn | Si | S | P | Cu | Ni | Mo | Cr |

| ≤0.08 | 0.5-2,5 | ≤0.90 | ≤0.030 | ≤0.040 | ≤0.75 | 9.0-11.0 | ≤0.75 | 18.0-21.0 |

Mechanical Properties of Deposited Metal

| Mechanical Properties of Deposited Metal | |

| Rm(Mpa) | A(%) |

| ≥550 | ≥35 |

Ho paka

Feme ea Rona

Pontšo

Setifikeiti sa rona